Automation

Clearance

EZ-Automation Solutions

Manufacturers face significant challenges daily. First, there's fierce competition for skilled workers amid rising labor and benefit costs, and delivering quality parts on time adds to the pressure. Automation can be a solution, offering efficiency and cost-effectiveness, especially with tight deadlines and workforce shortages.

Moreover, customers increasingly demand high mix, low volume quality parts. Yet, the variability in machining various parts poses hurdles for automation implementation. Additionally, modernizing for Industry 4.0/5.0 is complex. Integrating, operating, and maintaining such systems cost-effectively with existing staff skill sets is daunting.

However, automation is no longer futuristic; it's essential for success today. Simplifying the journey towards machine tending and lights-out machining is crucial. This requires user-friendly automation solutions, minimizing the need for advanced robotics or automation skills. It's about seamlessly integrating automation while controlling costs and easing job complexities for manufacturers.

If you want to dramatically improve your manufacturing potential, you need to automate. Today, you can enable your machine shop at any size to thrive with streamlined operations, improved processes, and a bottom line that reflects your success.

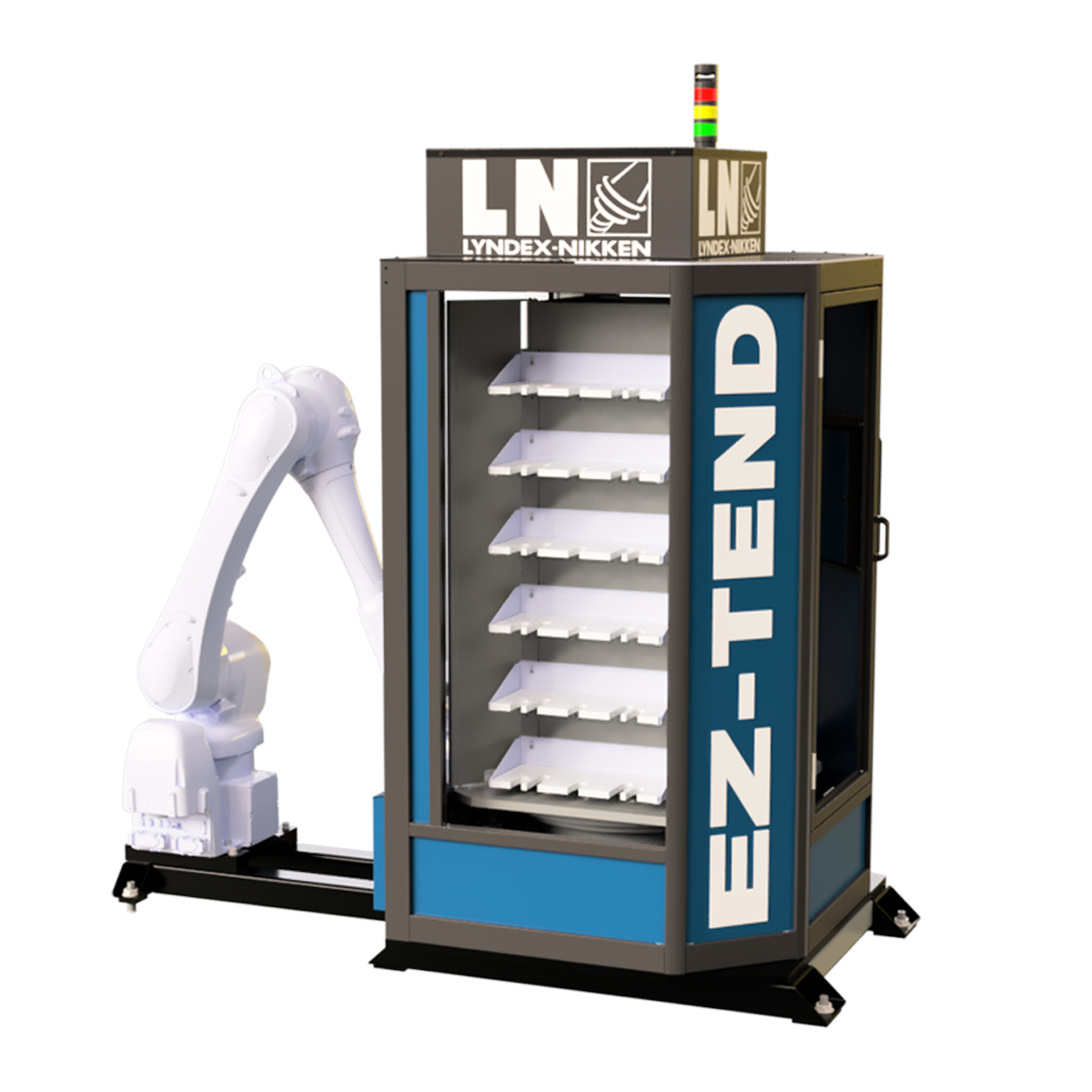

Lyndex-Nikken is your partner in growth and we’re here to make easy automation work for you with the EZ-Automation line of solutions - NO advanced robotics degree required. Lyndex-Nikken is already well-known on the shop floor for machine tool accessories and is now meeting the demands of industry with automation solutions. The EZ-Automation line of solutions includes:

- EZ-AutoCart: Easily Automate CNC Machine Tending

- EZ-Cob: CNC Machine Loading Automation Solution

- EZ-Bot: Automatic Work Changer for CNC Machines

- EZ-Tend: Modular CNC Machine Tending Platform

- EZ-SmartTower: Increase Machine Shop Efficiency with Machine Tracking System

EZ-AutoCart – Easily Automate CNC Machine Tending

The EZ-AutoCart machine tending solution empowers machine shops to automate the tending of CNC lathes, mills, and similar machines, significantly boosting spindle time and enhancing overall machine efficiency.

Additionally, designed into the software is the ability to expand functionality as you grow with your robot. You can harness the power of expressions to provide a flexible and robust solution for custom automation needs.

EZ-AutoCart integration capabilities:

- Includes 16 digital I/O to control peripheral devices

- Manage auto doors open/close

- Manage workholding conditions

- Optional hub provides data mining and quick change between multiple CNC machines

- Monitor CNC machine conditions

EZ-AutoCart vision capabilities:

- Includes integrated camera for 2/3D vision

- Optional software for 2.5D picking

EZ-AutoCart is designed for machine tending:

- Payload capacity: 18kg

- Reach: 1300mm

- Max joint speed: 435°/s

- Repeatability: +/-0.025mm

EZ-AutoCart system includes:

- Robot arm, cart, and tablet

- Support, including joint and hardware replacements

- Options (not included): Workholding, end-of-arm tooling, fixturing plates for the cart, safety scanners, and integration support

EZ-Cob – CNC Machine Loading Automation Solution

Automation is necessary to be competitive today and going forward. However, the robot or cobot is only one element of an automation solution. You need other elements to effectively build a complete automation solution. Those include a base module that the robot is mounted on, storage to hold blank parts, vises or pallets, and a wide range of peripherals. First and foremost, there are grippers, couplings, and automatic clamping devices for the components to be processed.

The machine tool must also be started by the automation, the door must be opened and last but not least, the automation must know when the machining cycle is finished. Although it is possible to write a separate robot program for each individual automation job, it is easier and more effective to have a job management system that manages and controls a wide variety of robot programs via parameters.

Once the hardware and software construction is complete, the question of safety arises. The operator is responsible for the overall safety assessment, including all components.

Add all of this up and automation may seem to be a daunting task. However, the easy and proven solution is the EZ-Cob for CNC machine loading automation. Your entry into automation is made easy with our starter package.

The compete EZ-Cob robot cell includes:

- Zero point clamping system with 4 pots

- Pneumatic vise and gripper jaws

- Door drive for automatic opening of machine tool

- Software for intuitive programming of the EZ-Cob

- Job management

- Double gripper for gripping blank parts

- Protective housing

With our large selection of proven components, you can select your own personal automation solution. All components are perfectly matched to each other. No adjustments or further engineering is required. Short delivery time enables you to boost production quickly with a ready-to-use solution. The EZ-Cob construction kit and its components are comprised of:

Easy to use software allows for efficient loading with a menu-guided assistant. So, you can create new loading jobs quickly and conviently on any terminal.

Easy to use software allows for efficient loading with a menu-guided assistant. So, you can create new loading jobs quickly and conviently on any terminal.

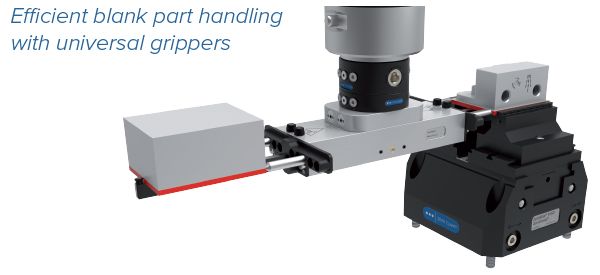

With a single gripper, components up to 160 mm deep can be gripped at the clamping edge. After processing, the component is gripped again at the clamping edge

with the same gripper and removed from the clamping device. This means that no special component-specific jaws are required.

The ZeroLoX® P80Z zero point clamping console, now with ball pressure quick change system, provides a universal interface for high-precision clamping of vises, pallets, and workpieces in seconds. Optimal machining can be achieved in combination with the ZeroVise® automation vises.

The ZeroLoX® P80Z zero point clamping console, now with ball pressure quick change system, provides a universal interface for high-precision clamping of vises, pallets, and workpieces in seconds. Optimal machining can be achieved in combination with the ZeroVise® automation vises.

Chip nests are a thing of the past with the ZeroVise® M80/M120 series - uncompromisingly designed for economy. With reversible jaws and jaw adapters, clamping ranges up to 167 respectively 207 mm are covered - no additional vise sizes are required. Spindle, center centring, and inner guides are completely covered and the outer contour is designed so that there are no chip nests.Time-consuming cleaning after use and problems with chips in the area of the spindle and guides are now a

Chip nests are a thing of the past with the ZeroVise® M80/M120 series - uncompromisingly designed for economy. With reversible jaws and jaw adapters, clamping ranges up to 167 respectively 207 mm are covered - no additional vise sizes are required. Spindle, center centring, and inner guides are completely covered and the outer contour is designed so that there are no chip nests.Time-consuming cleaning after use and problems with chips in the area of the spindle and guides are now a

thing of the past.

VIDEO: see the EZ-Cob in action:

VIDEO: see the EZ-Cob in action:

EZ-Bot – Automatic Work Changer for CNC Machines

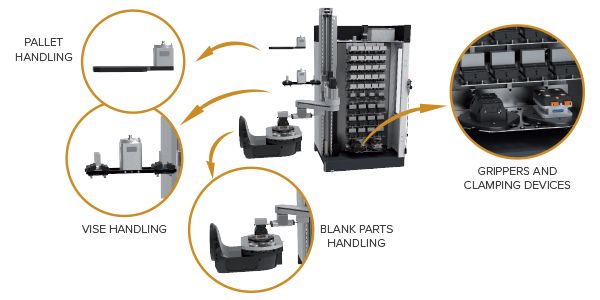

The EZ-Bot automatic work changer enables efficient blank part handling, vise handling, pallet handling, and automatic setup results in maximum machine running times while minimizing the time strain on skilled workers.

The loading robot with vertical double rack enables full-time parallel loading with minimum space requirements.

Here's how it works:

Features of the EZ-Bot 100V AWC include:

- Compact and flexible robot with double-sided, automatically rotating rack

- Footprint only approximately 2.9 m2

- Maximum storage capacity for blank parts, vises, pallets, and fixtures

- 100 kg handling weight, up to 640 mm component length

- Cycle time parallel set-up at the rear of the rack

- Access for the operator during set-up

- Designed for automated CNC machining with high flexibility and parts mix

VIDEO: see the EZ-Bot in action:

The EZ-Bot makes it easy to optimize your workflow with pre-set machining tasks without manual set-up. You can store your machining tasks already pre-equipped on mobile racks. A large number of jobs with different clamping devices and workpieces can be kept "ready to start" and immediately clocked in as required. Via job management, these are combined as desired and processed with all necessary set-up processes. So, manual set-up times are a thing of the past.

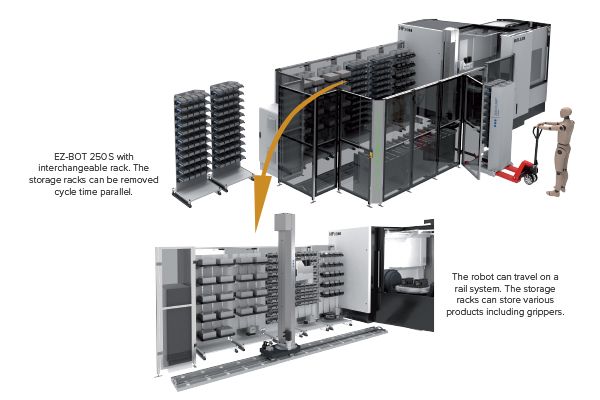

Features of the EZ-Bot 100S / 250S include:

- SCARA robot on linear rail axis

- 100 kg or 250 kg handling weight

- Maximum storage capacity for blank parts, vises, and fixtures with minimum space requirements

- Double gripper for shortest change-over times

- Any number of racks, equipped with workpieces, clamping devices, and grippers can be kept in stock

- Racks can be easily changed using a pallet truck

- Designed for automated CNC machining with high flexibility and parts mix

The EZ-Bot is proven technology already being used with many different machine tools - see it in action:

EZ-Bot on a Mazak machine:

EZ-Bot on a DMG Mori machine:

EZ-Bot on a Hermle machine:

EZ-Bot on a Heller machine:

EZ-Bot on a Grob machine:

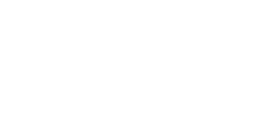

EZ-Tend – Modular CNC Machine Tending Platform

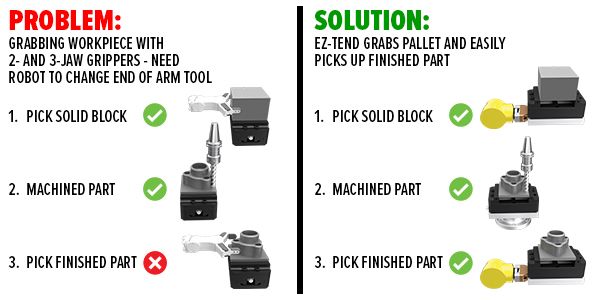

As a manufacturer, when trying to grab workpieces with 2- and 3-jaw grippers you can run into several challenges:

- Grab square/rectangle block

- Perform a machining operation

- No parallel surfaces to grab

Your automation journey starts to get complex; you now need a robot that can change its end of arm tool (EOAT) to accommodate the irregular shape. This is expensive and, in many cases, not possible.

What is needed is an automation solution that doesn’t deal with the changes in part geometry or the workholding issues. Utilizing a proven lean manufacturing technique, grabbing a single point on a pallet and moving the pallet and its contents to its destination will allow you to:

- Machine any shape

- Create part density

- Freely access sides of part as needed

Ideal for high mix/low volume production, the EZ-Tend modular CNC machine tending platform is an approachable, easy-to-use industrial robotic machine tending system. The EZ-Tend is an off-the-shelf automation experience. Great for the first time industrial robotic user entry level or the professional wanting ease of use and setup of industrial robot tending.

Watch the video to see the EZ-Tend in action:

EZ-Tend leverages lean principles by taking the application of lean manufacturing to the next level by using robots to tend the CNC machine to do lean tending. Its flexibility and power allow it to service milling centers with an option for turning centers.

The power of the EZ-Tend lies in the preconfigured pick and place positions. No robot programming required.

Manufacturers using the EZ-Tend will benefit with:

- One operator can run multiple machines

- Less operators mitigates cost increases

- Spindles run significantly more with assistance from automation

- High efficiencies equal improved capacity utilizations

- More throughput with the improved efficiencies

- Competition issues are mitigated due to better efficiencies, more throughput, and less cost

The EZ-Tend system uses mechanical design elements to provide protection from interaction with mechanical movement to offer the optimum level of operator safety. Optional state-of-the-art laser scanners are available.

The EZ-Tend system’s HMI (Human Machine Interface) is designed for the novice. The intent is to allow a non-robot programmer to create a pick and place routine using an icon base menu with just 3 screens to set up a new program. This simplicity is designed into the EZ-Tend system.

EZ-SmartTower – Increase Machine Shop Efficiency with Machine Tracking System

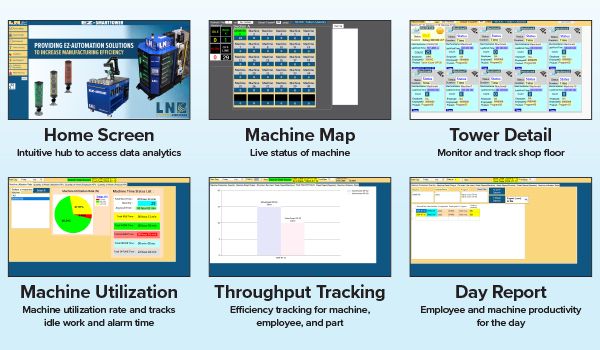

Embark on a new era of automation with the innovative EZ-SmartTower machine tracking solution that is easy to install on CNC lathes, mills, and similar machines. This cutting-edge technology empowers machine shops to automate the production data (i.e. uptime, idle time, error time, alarms, part making, operators) collection, enabling data analysis to identify bottlenecks, make improvements, increase spindle time, and enhance overall machine efficiency. Embrace modern technology and the seamless integration of automation into your manufacturing process.

The EZ-SmartTower is a modular, easy to use, and cost-effective automation solution that is scalable across all machines in your shop. It enables stress-free entry into Industry 4.0/5.0 or being a smart factory that helps you analyze your machine ROI. The EZ-SmartTower not only provides comprehensive data tracking for machine performance but also offers real-time insights, enabling businesses to optimize processes, track employee contributions, and boost overall operational efficiency.

Using the EZ-SmartTower can provide:

Using the EZ-SmartTower can provide:

• Enhanced overall shop efficiency by minimizing downtime and maximizing machine utilization

• Cost effective measurement of machine throughput by analysis of operator and machine performance

• Machine data to facilitate in-depth analysis for process optimization and bottleneck identification

• Visual feedback to empower operators to stay informed, enhancing workflow efficiency

• Data for employee incentives based on performance

• Real-time status of machines allowing for on-the-fly decision making

The capabilities of the EZ-SmartTower include:

• Accurately logs machine cycle counts

• Records idle, cycle, and error times for spindle efficacy tracking

• Logs data for analytics with details such as operator name, machine name, and part name

• LED light indicates machine status while displaying current cycle time or idle time

• WiFi enables data to transfer in real time

• Included Apps allows data collection of all machine tools

• Data output in charts or Excel spreadsheet can be refined with filter criteria for daily or weekly analysis

Videos: Why Manufacturers Choose Lyndex-Nikken Solutions for Machine Tool Accessories and Automation

Hear and see for yourself how Lyndex-Nikken quality machine tool accessories and automation provide optimal machining solutions for: