Work Holding

Clearance

WORKHOLDING

Clamping Technology - Secure & Reliable

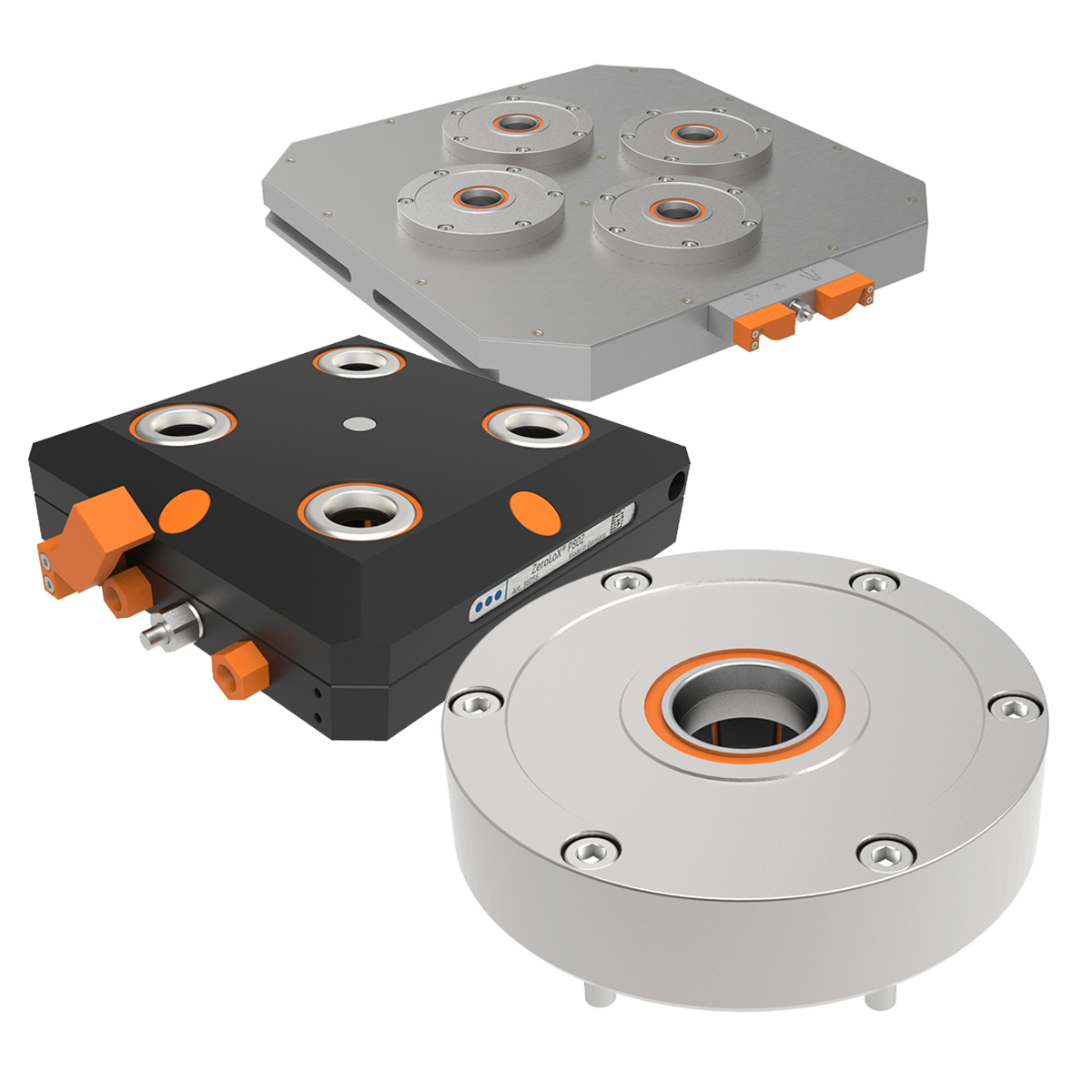

Lyndex-Nikken offers new clamping technology - the Zero Point clamping system and modular clamping rail system enable manufacturers to minimize set up and changeover time.

The Zero Point clamping system is a modern alternative to the conventional T-slot table. Since only one clamping stud is required, set-up times are drastically reduced and machine capacity is increased. Maximum flexibility and process reliability are guaranteed throughout the entire production process. We guarantee high clamping force with maximum accuracy.

The Zero Point clamping system boasts maximum user-friendliness due to:

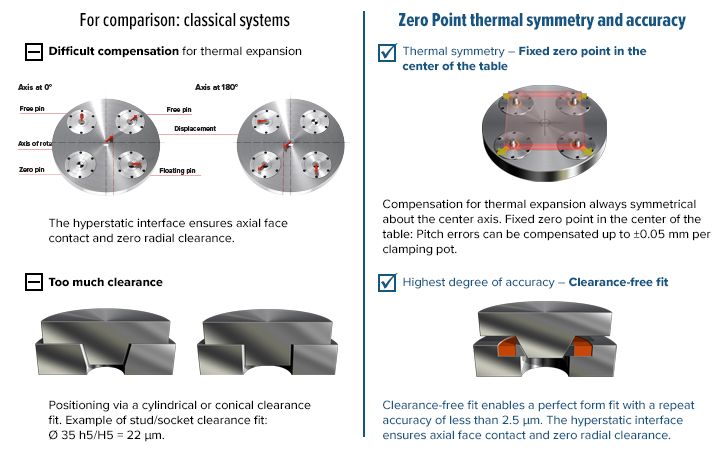

- Highest Degree of Accuracy - repeat accuracy of less than 2.5 µm

- Simple Logistics - just one type of clamping stud

- Key Benefit - thermal symmetry

- No Tilting - uncomplicated joining and removing

- One System for the Entire Process - milling, turning, right up to quality assurance

These benefits enable a reduction of setup times by up to 90%, 330 hours of additional production time per year, and save approximately $33,200 per year.

Conventional setup process consists of:

1. Clean the machine table

2. Clean the clamping device contact surfaces

3. Position via the slot nuts

4. Align

5. Fasten with clamping screws

6. Determine the zero points

7. Start the program

8. End the program

The biggest disadvantage is it is difficult or even impossible to interrupt the process (completely remove the component from the machine table). The machine must be standstill while you are doing this or the workpiece is scrapped.

Using the Zero Point clamping, the process takes only 10% of the time it takes using the conventional setup process:

1. Clean the machine table (reduced)

2. Clean the clamping device contact surfaces <biggest time factor completely omitted>

3. Start the program

4. End the program

The biggest benefit is the process can be interrupted at any time without a problem. So, you get continued machine use in a variety of applications.

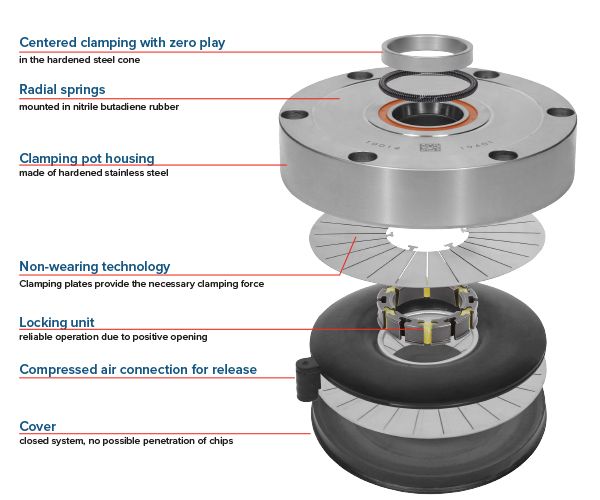

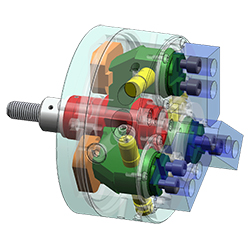

The center piece of the Zero Point clamping system is a simple assembly with few components and very high repeat accuracy for at least one million cycles. It is a pneumatic system with only 5.5 bar air pressure required to release the clamping studs.

When comparing a traditional or classic clamping system to the Zero Point clamping system, the traditional or classic clamping system has difficulty with compensation for thermal expansion and has too much clearance - while the Zero Point clamping system provides thermal symmetry and accuracy.

The biggest benefit of the Zero Point clamping system is it is easy to handle from a logistical point of view. There is no differentiation between zero pins, floating pins, or free pins. Only one clamping stud type is required. Watch the video to learn more:

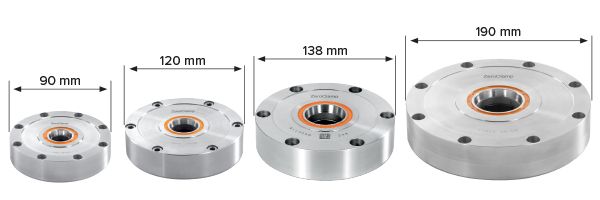

Versatile clamping pots are available for standard applications to automation. Clamping pots have a clamping force of 12.5 to 60 kN. Additional variants with position monitoring function and air coupling are available for automated operation. All clamping pots are available with indexing holes (anti-twist device for single use).

Watch the video to hear why Marc Manteufel, Manufacturing Engineering Manager, at A to Z Machine Company selected the Lyndex-Nikken Zero Point clamping system for a long-term 10 year project - robust, quick set up and change over.

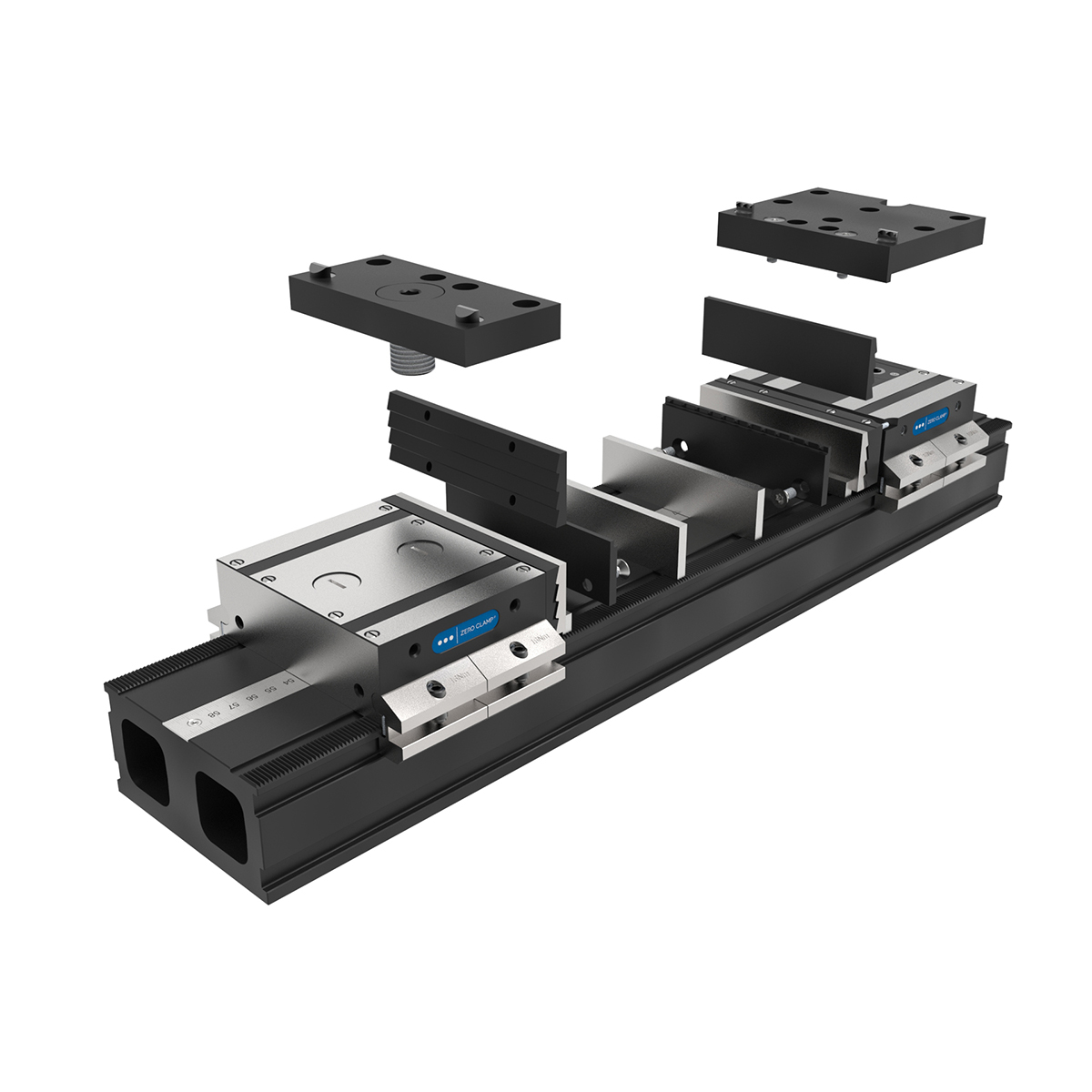

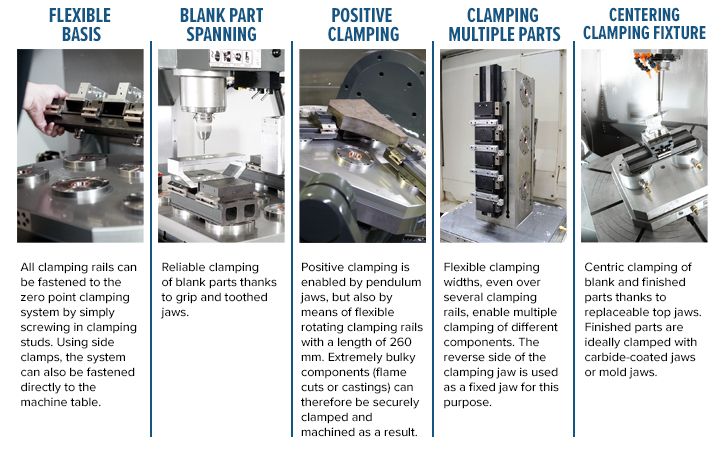

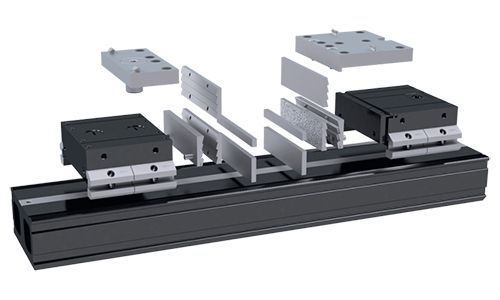

The modular clamping rail system is an alternative to conventional vices for flexible use on the machine tool. Our multiple clamping systems enable safe operation even in heavy-duty machining. We enable any clamping width and multiple clamping with just one system due to endlessly connectable clamping rails.

The two SL080 and SL120 modular clamping rail systems with a clamping force of 20 kN or 40 kN enable safe operation even in heavy-duty machining processes. All clamping widths possible due to clamping rails which can be coupled together infinitely. Modular clamping rail system 80 and 120 offer:

- Individual clamping widths - suitable for both small and large workpieces thanks to clamping rails which can be coupled together infinitely

- Multiple clamping - single and multiple clamping possibilities (flexible fixed jaws) in a 2 mm grid

- Unique clamping possibilities - clamping complex workpieces via rotating clamping rails (260 mm)

- Modular design - a large variety of clamping jaws and direct fitting on the zero point clamping system

Using the modular clamping rail system offers benefits including high pairing accuracy of 0.03 mm due to clamping rails being coupled together infinitely. The modular rail system has lower height compared to conventional vices - 50% less due to the maximum utilization of the Z travel distance. Finally, the modular rail system is user-friendly due to its low weight, in fact it has a -70% reduction in weight compared to conventional vices. There are many unique features of a modular clamping rail system that make it ideal for day-to-day production work.

See for yourself how you can benefit from using a modular clamping rail system - watch the video:

A comprehensive range of accessories are available for the modular clamping rail system that enables you to clamp blank and finished parts and clamp accurately according to the contours of the part.

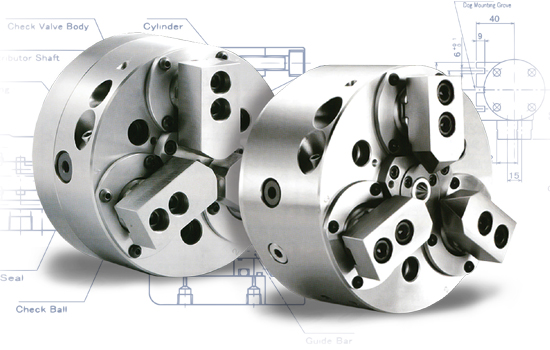

Hydraulic Power Chucks – Secure & Reliable Clamping

Hydraulic power chucks are workholding devices used in manufacturing to secure and clamp workpieces during machining operations on a lathe or turning center. They utilize hydraulic pressure to apply gripping force to the workpiece, ensuring secure and reliable clamping.

Here are some challenges that manufacturers may face where hydraulic power chucks can provide solutions:

- Secure Clamping: One of the primary challenges in machining is ensuring that work pieces are securely held in place during cutting operations. Hydraulic power chucks provide high clamping force and uniform pressure distribution, minimizing the risk of workpiece movement or slippage during machining.

- High Precision Machining: Achieving precise dimensional accuracy and surface finish is essential in manufacturing. Hydraulic power chucks offer excellent concentricity and repeatability, ensuring consistent part quality by securely holding the workpiece in the correct position relative to the cutting tool.

- Heavy-Duty Machining: Machining heavy or irregularly shaped work pieces can pose challenges in terms of clamping force and stability. Hydraulic power chucks are capable of handling a wide range of workpiece sizes and shapes, providing robust clamping force to accommodate heavy-duty machining applications.

- Quick Changeovers: Minimizing setup time and changeover time between workpieces is critical for maximizing machine utilization and productivity. Hydraulic power chucks feature fast actuation and clamping mechanisms, allowing for quick and efficient work piece changes without sacrificing clamping force or accuracy.

- Reduced Tooling Costs: In traditional machining setups, special tooling or fixtures may be required to accommodate different workpiece sizes and shapes. Hydraulic power chucks offer versatility and adaptability, eliminating the need for custom tooling and reducing tooling costs associated with fixture design and fabrication.

- Enhanced Machining Efficiency: Hydraulic power chucks enable continuous machining operations by securely holding the workpiece in place without the need for constant manual adjustment or monitoring. This allows machinists to focus on other tasks, leading to increased machining efficiency and throughput.

- Compatibility with Automation: As manufacturing trends towards automation and lights-out machining, compatibility with automated systems becomes increasingly important. Hydraulic power chucks can be integrated with robotic arms or CNC machine tool loaders, allowing for seamless automation of workpiece loading and unloading processes.

Overall, hydraulic power chucks offer a reliable and versatile solution to a variety of machining challenges. By addressing these challenges, manufacturers can improve productivity, reduce downtime, and enhance overall machining efficiency.

Durability & Precision in a Workholding Solution

With a wide selection of 2-jaw, 3-jaw and specialty chucks designed to handle any workholding challenge, features include:

- Low maintenance, high performance

- Capable of clamping over workpieces with uneven surfaces and a large range of diameters

- Maintains powerful clamping at high RPM

- Large through hole bores available for bar feeding

- Fully sealed structure reduces frequent greasing and prevents coolant leaks

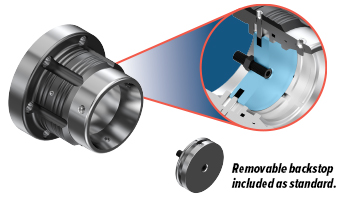

Quick Change Flex Collet (QCFC) Chucks – Flexibility, Rigidity, Clearance & Accuracy

Quick change flex collet (QCFC) chucks can be used in a variety of turning center applications including high volume, low mix production shops for bar feeding or robot loading. In fact, a 1/16” total gripping range, 1/32” below nominal size and 1/32” above nominal range, makes QCFC chucks ideal for bar feeding applications. QCFC chucks can also be used in low volume, high mix job shops machining varying sized parts and varying shape materials.

Benefits of using QCFC chucks include:

- Fast collet changes

- High accuracy

- Wide clamping range

- Easy mount design

- Less change-over time

- High RPM

- Compact design

- Durable, wear resistant collets

- High clamping forces

Fast collet changes are a reality as they can be done in 10 seconds, and quick and easy installation is possible by switching from a 3-jaw chuck to a collet chuck.

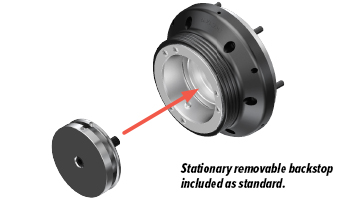

A removable backstop is included as standard to enhance the versatility, customization, and efficiency in machining operations. Machinists can quickly and easily adjust the chuck to accommodate different workpieces, optimize setup configurations, and improve machining performance while ensuring safety and precision.

QCFC chucks are constructed of wear resistant hardened chromium steel and are designed for rigidity, clearance, and accuracy. A small nose diameter enables increased tool clearance for improved access, reach, precision, chip evacuation, and compatibility with complex workpieces. Additionally, QCFC chucks are balanced for high RPM for production flexibility.

The types of QCFC chucks include:

Pull Back-Stop Chuck: Maximum rigidity allows for roughing and finishing as would be done with a 3-jaw chuck. The pull back-stop chuck provides axial collet movement in a 1-piece body design with easy installation. It is designed with flexibility for backstop or through-material applications. Maximum gripping range of 0.062" accommodates oversized/undersized material.

Pull Back-Stop Chuck: Maximum rigidity allows for roughing and finishing as would be done with a 3-jaw chuck. The pull back-stop chuck provides axial collet movement in a 1-piece body design with easy installation. It is designed with flexibility for backstop or through-material applications. Maximum gripping range of 0.062" accommodates oversized/undersized material.

Watch the video to learn more about the components of QCFC pull back collet chucks, and see how to install the machined draw screw into the collet chuck, how to thread the chuck onto the draw tube of the machine spindle, and how to check run out.

Dead Length Modular Chuck: A 2-piece design allows for modular flexibility of the collet chuck. Offering fixed axial collet location, this modular design allows for variable machine taper mounts within the same series and reduced weight during assembly. Taper-to-taper design provides easy installation with maximum accuracy.

Dead Length Modular Chuck: A 2-piece design allows for modular flexibility of the collet chuck. Offering fixed axial collet location, this modular design allows for variable machine taper mounts within the same series and reduced weight during assembly. Taper-to-taper design provides easy installation with maximum accuracy.

Watch the video to learn more about the components of QCFC dead length collet chucks, and how to install the base on the machine spindle, how to indicate the base while tightening to achieve zero runout, how to install the threaded body onto the draw tube, how to install the collet, how to check the runout, and how to install the back stop into the dead length collet chuck.

For both a QCFC pull back-stop chuck and a dead length modular chuck, the draw screw plays a crucial role in the operation of a QCFC to pull the collet into the chuck body. The draw screw provides precise control over clamping force and ensuring secure workpiece gripping. So, you need to get draw screw measurements for the proper assembly, alignment, and performance of a quick change flex collet chuck. Watch the video to learn how to thread the draw screw, take draw screw design measurements, and attach the modified draw screw to the base of the chuck body. This same process can be done for dead length or pull back chucks.

By following these instructions diligently, manufacturers can maximize the reliability, accuracy, and longevity of the collet chuck, thereby enhancing machining efficiency and quality.

Quick Change Flex Collets – Fast Changes in Seconds

Quick change flex collets are available in smooth collets, hex collets, or serrated collets. Collets can be switched to any size within seconds, not minutes.

Increased precision, gripping force, and clamping range of a quick change flex collet benefits manufacturers by enabling them to achieve higher machining accuracy, stability, versatility, and efficiency, leading to improved productivity, quality, and competitiveness in the marketplace.

- Quick change flex collet accuracy is 0.0004” or better resulting in increased precision.

- Increased gripping force is possible due to the collet collapsing parallel to the workpiece, not angular.

- Increased clamping range is due to quick change flex collets allowing workpieces to be up to ± 0.0312” from nominal diameter.

Videos: Why Manufacturers Choose Lyndex-Nikken Products

Hear and see for yourself how Lyndex-Nikken quality products provide optimal machining solutions for: